For over 20 years we’ve been producing control systems for paper cutters. We’ve sold hundreds of devices, most of them in Europe, but we also have happy customers in Africa, Asia, and America.

Our readers and programmers are designed for retrofitting old guillotines and they are compatible with most of the popular brands for example Polar, Ideal, Wholenberg, Maxima, and Seypa Perfecta.

All of our devices work with millimeters, centimeters, and inches.

Our devices are sold with full installation sets.

Automatization of the back gauge’s control system allows:

- Reducing the number of defects

- Increasing of precision

- Increasing of work pace

As a producer, we provide:

- Two years guarantee period for PD-04 and PD-04B, one year for OD-08

- Full remote (via e-mail or telephone) support in installing our devices

Our products:

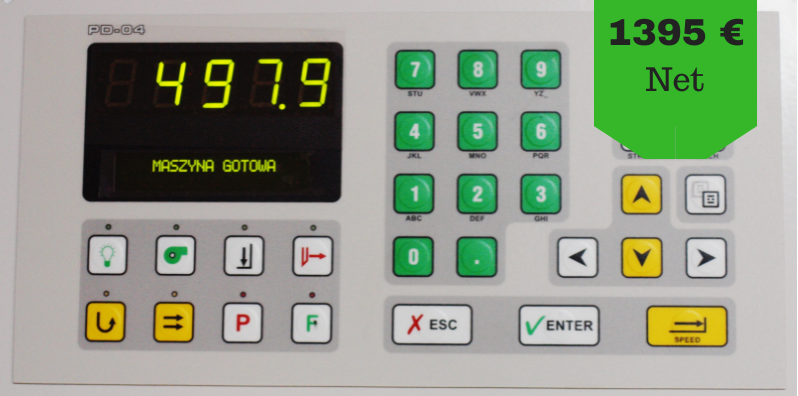

PD-04 programmer

The most important functions:

- Move to relative and absolute position

- Saving 100 programs, 80 steps each

- Controlling light line and air table

- Cutting into stripes

For whom?

Big printing houses that need to quickly cut a lot of paper into many different formats.

Installation set

- PD-04 programmer unit

- Encoder

- Encoder-programmer cable

- TBMF-4, TBMF-5, TBMF-6, TBMF-8, TBMF-8 connectors

- Power supply unit

- Elastic coupling

- Single-phase 0,75 kW* inverter

- Manual

- Warranty card

PD-04B programmer

The most important functions:

- Move to relative and absolute position

- Saving 10 programs, 20 steps each

- Cutting into stripes

For whom?

Medium-sized printing houses that need to quickly cut a lot of paper into a few standard formats.

Installation set

- PD-04B programmer unit

- Encoder

- Encoder-programmer cable

- TBMF-4, TBMF-5, TBMF-6, TBMF-8, TBMF-8 connectors

- Power supply unit

- Elastic coupling

- Single-phase 0,75 kW* inverter

- Manual

- Warranty card

OD-08 reader

The most important functions:

- Displaying relative, absolute, or relative and absolute position

- Showing whether the position was reached by a backward or forward move

- Affordable price

For whom?

Small printing houses that value accuracy.

Installation set

- OD-08 touchscreen

- Control unit

- Encoder

- Contro unit touchscreen cable

- Encoder-control unit cable

- TBMF connectors

- Elastic coupling

- Manual

- Warranty card

*Some machines require a three-phase inverter, depending on the motor’s machine. Contact us and we will help you to choose the right option for you.

A detailed comparison of PD-04 and PD-04B:

| PD-04 | PD-04B | |

|---|---|---|

How to buy?

You can send an inquiry through a form or send us an email.

What info do you need to submit and why?

- Destination country – so we can quote delivery costs and time.

- Are you a reseller or an end client (printing house) – if you are an end client we can check if we have any distributors in your area who can help you with an installation.

Inquiry form

PD-04 functions and parameters

A detailed list of functions:

• Possibility of saving 100 programs up to 80 steps each

• Relative (by distance) and absolute (to position) move

• Semiautomatic work with the program (after every cut, the beam is moved to the position specified in the next program’s step)

• Paper ejection function

• Calculator with basic arithmetic functions

• Cutting into strips – special mode for cutting visit cards

• Learning mode – the program is saved by executing a sequence of cuts

• Control of air table and light line

• Knife’s cuts counter

• Large – 20 mm, red or green LED which displays current measurements and special alphanumeric LCD with the backlight which shows 2 lines up to 20 characters each

• Large, ergonomic, and readable keyboard, resistant to dirt and dust

• Multilingual support (Polish, English, and Russian)

• Possibility of installation in almost any paper cutter

• Calculator with elementary arithmetic functions

Technical parameters:

| Parameter | Value |

| Dimensions | height: 185 mm, width: 345 mm, the depth: 25 mm |

| Casing | metal |

| Weight | 1,9 kg |

| Power supply | 230 VAC / 2*24VAC |

| Power consumption | 8 W |

| Load capacity of relay outputs | max. 2A / 24VDC, max. 0,5 A /120 VAC |

| Encoder’s power supply | max. 200mA |

| Encoder’s outputs type | OC (Open Colector), PP (Push – Pull) |

| Encoder’s resolution | from 10 to 2550 ppr |

| Controlling the inductive motor | through the inverter |

| Pitch of the screw | from 1 up to 25,5 mm/turnover with the resolution 0.1 mm |

| Measurement units | millimetres, centimeters, inches |

| Resolution | 0,1 mm |

PD-04B functions and parameters

A detailed list of functions:

• Possibility of saving 10 programs up to 20 steps each

• Relative (by distance) and absolute (to position) move

• Semiautomatic work with the program (after every cut, the beam is moved to the position specified in the next program’s step)

• Paper ejection function

• Cutting into strips – special mode for cutting visit cards

• Learning mode – the program is saved by executing a sequence of cuts

• Knife’s cuts counter

• Large – 20 mm, red or green LED which displays current measurements and special alphanumeric LCD with the backlight which shows 2 lines up to 20 characters each

• Large, ergonomic, and readable keyboard, resistant to dirt and dust

• Multilingual support (Polish, English, and Russian)

• Possibility of installation in almost any paper cutter

Technical parameters

| Parameter | Value |

| Dimensions | height: 185 mm, width: 345 mm, the depth: 25 mm |

| Casing | metal |

| Weight | 1,9 kg |

| Power supply | 230 VAC / 2*24VAC |

| Power consumption | 8 W |

| Load capacity of relay outputs | max. 2A / 24VDC, max. 0,5 A /120 VAC |

| Encoder’s power supply | max. 200mA |

| Encoder’s outputs type | OC (Open Colector), PP (Push – Pull) |

| Encoder’s resolution | from 10 to 2550 ppr |

| Controlling the inductive motor | through the inverter |

| Pitch of the screw | from 1 up to 25,5 mm/turnover with the resolution 0.1 mm |

| Measurement units | millimetres, centimeters, inches |

| Resolution | 0,1 mm |

OD-08 position reader

A detailed list of functions:

- displaying relative, absolute, or relative and absolute position,

- shows whether the position was reached by a backward or forward move

- measurement in centimeters, millimeters, and inches

- high measurement resolution: 0,1 or 0,01 mm; 0,01 cm; 0,001 inch

Technical parameters

| Parameter | Value |

| Dimensions | height: 75 mm, width: 110 mm, depth: 25 mm |

| Casing | metal, can be fitted into a board |

| Touchscreen | 2,8″ resistive |

| Power supply | ~230V |

| Power consumption | 8 W |

| Pitch of the screw | millimeters, centimeters, inches |

| Encoder’s resolution | from 1 to 3600 ppr |

| Measurement resolution | 0,1 or 0,01 mm; 0,01 cm; 0,001 inch |

| Measurement units | millimetres, centimeters, inches |

Frequently asked questions

- Who can install PD-04, PD-04B, and OD-08?

- How long does the installation take?

- Can I install your device on my machine?

- What do I need apart of thing from the installation set?

- What signals PD-04 and PD-04B use and should I buy inductive sensors?

- How to check which inverter I need?

- I have your device installed on my machine but I don’t have manual/service codes, what should I do?

- Do you keep your devices in stock or are they made to order?

1. Who can install PD-04, PD-04B, and OD-08?

Simple answer: OD-08 – almost anyone. PD-04 and PD-04B – someone with knowledge about machines and electricity.

Explanation: Installation is not complicated, our manuals are as detailed and as step-by-step as possible, and we provide remote support with the installation.

OD-08 has very basic functionality and because of that installation is very simple and with minimal changes to the machine’s circuits.

Installation of PD-04 and PD-04B requires connecting an inverter (part of the installation set) to the original motor of the machine. Programmers use more signals than OD-08 so more changes in the original machine’s circuits are needed.

More than half of installations are made by employees of printing houses that buy PD-04 and we’ve never had a failed installation.

2. How long does the installation take?

OD-08 – Less than 8 hours.

PD-04 and PD-04B – Usually 2-3 working days. Some technicians who have experience in installing our devices do it in 8-12 hours. Our clients who install PD-04 for the first time usually need 3-5 days.

3. Can I install your device on my machine?

OD-08 – The only requirement for installing OD-08 is that the machine has a propelling screw and it’s possible to connect the encoder (which is part of the installation set) to it.

PD-04 and PD-04B – Our programmers can be installed on almost all machines, but some installations are more complicated. Here are three things that can make installation more complicated:

- integrated cutting control – PD-04 and PD-04B don’t have integrated cutting control while many newer machines have one controller for moving and cutting. PD-04 and PD-04B can control moving in this kind of machine, but you’ll need a separate electronic module for cut control.

How to check: if your machine was made before the year 2000 then it probably doesn’t have integrated cutting control. If you have a newer machine with a broken controller: if you can’t control movement, but you can still make a cut – the cutting control is not integrated. - no driving screw – standard installation requires mounting encoder on the driving screw. There are some, very rare cases where machines have cable drives instead of driving screws. In this case, it is possible to install PD-04 with a linear scale instead of an encoder. If you have a cable-driven paper cutter and you want to install our system in it, contact us and we will help you to find the right solution.

- servo drive – PD-04 and PD-04B were designed to control AC motors through an inverter, but they can be connected directly to some servo drives. If you have a machine with a servo drive, contact us, and we will check if our controller can work with it.

4. What do I need apart of thing from the installation set?

OD-08 – You will need: some standard cables, and something (like a small sheet of metal) to hold the encoder in place. You may need 1 sensor to use as a calibration limit switch if your machine doesn’t have one. You can buy an inductive sensor from us, but any NPN sensor can be used. Everything else you will find in the set.

PD-04 and PD-04B – You will need some standard cables, and something (like a small sheet of metal) to hold the encoder in place. You need to make sure your machine has the required limit switches. A description of signals used by PD-04 and PD-04B is in the next question.

5. What signals PD-04 and PD-04B use and should I buy inductive sensors?

PD-04 and PD-04B use signals from 6 limit switches:

- Maximal position – it has to be a mechanical switch and almost always it’s already in the machine. We don’t sell them as paper cutters are built differently and there isn’t one mechanical limit switch that suits them all.

- Minimal position – the same thing as maximal position limit switch: usually it’s already in the machine, it has to be mechanical, and we don’t sell them.

- Upper knife position – if the machine had previously any kind of control system, it probably already has it. It can, but doesn’t have to be mechanical. You can buy NPN inductive sensor from us to use if your machine doesn’t have it.

- Upper knife position – the same as the upper knife position: if it’s there, you can use it, if it’s not, you can buy NPN inductive sensor from us.

- Calibration limit switch – it’s often already in machines that had control systems, but it’s not always there. It can be mechanical, it can be an NPN inductive sensor. It should be mounted somewhere halfway between the minimal and maximal positions.

- False clamp sensor – you need it only if you use a false clamp. As the false clamp is usually made of plastic, you can’t use an inductive sensor, you need a mechanical limit switch for that.

6. How to check which inverter I need?

In general, if the motor that is responsible for moving the paper can be powered up from 3x230V, then a single-phase inverter is suitable, otherwise, you’ll need a three-phase inverter.

If you are not sure which one will be good for you, take a photo of the motor’s nameplate and send it to kontakt@chip-elektronika.pl and I’ll check it for you.

7. I have your device installed on my machine but I don’t have manual/service codes, what should I do?

Contact us and we will send you codes and the manual.

There were some changes in PD-04 through the years, service codes stayed the same but some settings changed. If you can, check the serial number of your device. You’ll find it on the back of the metal casing, in the upper right corner, it consists of 9 digits.

8. Do you keep your devices in stock or are they made to order?

We keep our devices in stock.